Efficient and safe pipe installation, maintenance and repair

- Aug 7, 2025

- 7 min read

The maintenance of complex and ageing drinking water distribution networks is a significant challenge for water utilities. Careful planning and the use of the right tools help secure a continuous supply of safe water and manage the disruptive effects of maintenance operations. However, when pipes burst, immediate action is required.

In this post, we present three innovative water utilities (VA SYD and Sydvatten AB in Sweden, and

Farys in Belgium), and how they deployed BactoSense as an emergency response tool for pipe bursts.

The utilities successfully used the fully automated instrument to monitor the water quality during pipe flushing. They aimed to reduce water consumption and mitigate the adverse effects of disruption, while ensuring a safe and continuous supply to their consumers.

Maintaining drinking water distribution networks is disruptive and expensive

Drinking water distribution networks are built and maintained to deliver drinking water safely and reliably to consumers. Such networks often run underground, can be highly complex and consist of thousands of kilometres of pipes, making them particularly challenging to maintain. Nowadays, many pipe systems are old and stressed, posing a permanent risk of pipe bursts.

One challenge of pipe maintenance operations is ensuring the safety of consumers. Maintenance works and emergency repairs bear the risk of introducing contamination to the water distribution system. Flushing the pipes thoroughly and verifying safe water quality are therefore imperative for commissioning, scheduled maintenance and emergency repairs.

Another challenge is the disruption caused by maintenance work, particularly after unexpected pipe bursts. Temporary alternative water supplies must be provided immediately. Maintenance personnel and equipment must be allocated and deployed. Additionally, construction sites must minimise the impact on local traffic, businesses, and residents.

A study conducted by VA SYD, one of Sweden‘s largest water utilities, concluded that the total direct and indirect cost to society of a single pipe burst in a city can be in the order of one million Euro.

In this analysis, most of the contributing cost factors (such as traffic and business interruption costs) are time-dependent, with increasing costs for more extended downtime. The duration of an interruption in urban areas, therefore, has a significant economic impact, and tools capable of shortening the duration are of great value.

Add a BactoSense to your pipe maintenance toolbox

BactoSense, the online flow cytometer, is a powerful solution that ensures water safety and reduces downtime.

The instrument is used in pipe maintenance and incident response workflows to continuously monitor the microbiological quality of the distribution network during interruption and commissioning.

BactoSense data can be used to assess risks and make appropriate decisions.

Examples include the surveillance and timing of pipe flushing processes, as well as the identification of water quality deteriorations in other parts of the network due to temporary network interruptions (e.g., stagnation).

Compared to tedious and time-consuming lab tests, BactoSense results are available after 30 min, and the instrument easily discriminates bacteria from inorganic particles and debris. The device can be configured to sample automatically from a water source in regular intervals, or it can be used to measure manually collected grab samples.

It‘s an industrial solution with a simple user interface designed to be operated by everyone.

Monitoring the microbial water quality during pipe operations

BactoSense helps to work safely and efficiently on a water distribution network. For this purpose, instruments are typically integrated upstream and downstream of the maintenance site.

BactoSense directly measures the effects of the operations on the microbiological water quality by quantifying either the total or intact bacterial cell concentration. In the following overview, a typical implementation scheme for pipe installation, maintenance, and repair is shown:

A) Around the Maintenance Site

1. Set up a Reference and Monitoring Point

Identify a reference point upstream of the pipe operations, install BactoSense and start monitoring to establish a reference baseline.

Identify a sampling point downstream of the pipe operations and install BactoSense to monitor the flushing water.

2. Measure the Evolution of the Water Quality

Compare the microbial water quality of the monitoring point with the reference point during pipe filling and flushing.

3. Determine the Pipe Integration Timepoint

Verify that the water quality profiles obtained from the monitoring and reference points are similar. Then safely reconnect the new or maintained pipe segment into the distribution system.

B) In Other Parts of the Network

1. Set up Critical Control Points

Analyse your distribution network (e.g., the hydraulic model) and predict the effect of pipe operations (e.g., stagnation).

Identify critical control points (CCPs) for continuous monitoring throughout the operations.

Install BactoSense at all critical control points and start monitoring.

2. Monitor Critical Control Points

Continuously monitor the critical control points and take immediate action if the water quality deteriorates.

CASE STUDIES:

How can online bacteria measurements help reduce downtime after pipe repairs?

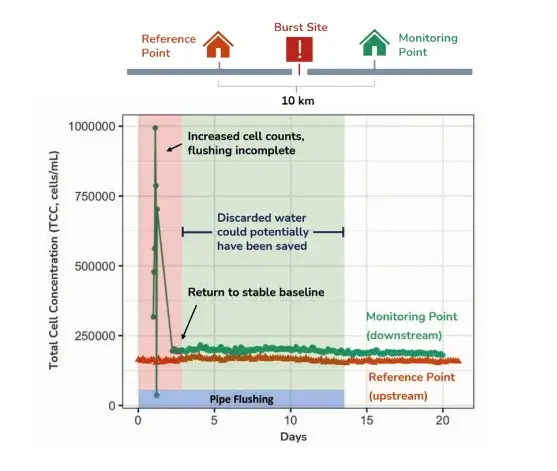

In 2018, a pipe connecting two Swedish villages burst. Immediately after the incident, two BactoSense instruments were installed to assess the microbiological dynamics during the repair works.

The first instrument, installed upstream of the burst site, continuously monitored bacterial cell concentrations to establish a reference baseline. Downstream of the burst site, the second instrument monitored the cell concentration in the flushing water to determine the effectiveness of the flushing process, which was scheduled for a fixed period of two weeks.

As shown in Figure 3, the total cell concentration measured at the monitoring point was highly dynamic and strongly elevated after the start of the flushing process. Within less than three days, however, the cell concentrations returned to baseline values and remained stable afterwards, indicating that pipe flushing had been effective.

Having such data at hand allows the operators to move from fixed (as in this case) to adaptive flushing durations, saving large quantities of clean drinking water and returning to regular operation much earlier. As an additional positive effect, minimising downtime also reduces the risk of microbial issues emerging in other parts of the network.

How BactoSense prevented the disruption of the water supply in Flanders

Farys is a Belgian drinking water supplier, maintaining close to 12‘000 km of low-pressure water networks and 700 km of high-pressure piping, serving 1.4 million consumers in Flanders.

In 2018, just before Christmas, a pipe burst interrupted the water supply by one of the high-pressure collectors transporting drinking water from the Brussels area towards Brakel. The event limited the supply to the 30‘000 m³ reservoir in Brakel. Hence, Farys responded immediately and deployed personnel and equipment to repair the pipe segment.

As part of Farys‘ incident response strategy, a BactoSense instrument was installed to monitor the microbial water quality during the repair work. The device proved particularly useful in validating the pipe flushing efficiency and assessing the effects of shock chlorination on the microbial load after the repair.

As Farys established reference cell concentrations upstream of the pipe burst, the operators could precisely determine at which point the repaired pipe segment met the quality standards to be reconnected to the network.

Minimising the downtime was essential for ensuring a continuous water supply to the residents and businesses within a substantial part of the Farys network. The immediate test results from BactoSense were of valuable assistance to the conventional water quality tests (heterotrophic plate counting) conducted in the lab.

They helped to prevent the supply reservoir from running empty. Therefore, the rapid deployment of BactoSense to the field provided key information for the risk assessment, such that only two days after the incident, the repaired pipe segment was back in operation, ensuring an uninterrupted supply of safe water in Flanders.

Why invest in BactoSense?

Preventing disruption and microbial issues in an economical way

BactoSense is a powerful tool for maintenance professionals and incident responders. It is used to assess risks during pipe maintenance and repairs appropriately, enabling informed decisions based on evidence.

The instrument can be easily deployed where needed and automatically measures the water‘s microbial quality continuously and comprehensively.

How to secure a swift return on your investment:

1. Prevent or reduce disruptions in urban areas

One million Euros - that‘s the estimated total cost to society of a single pipe burst occurring in the city of Malmö, according to one of Sweden‘s largest water utilities.

The longer the interruption, the higher the cost. Therefore, waiting for lab results can easily cost tens to hundreds of thousands of Euros. BactoSense provides instant feedback on the microbial water quality during pipe commissioning.

As shown in the second case study (pipe burst threatening supply in Flanders), BactoSense technology enabled the right decisions to be made under time pressure. It prevented the water supply interruption to an entire region. This case had a significant impact on risk management.

Local legislation typically mandates lab tests to verify the microbial safety of the water. However, waiting days for the results is not feasible, as reservoirs are depleting rapidly, costs of interruptions are escalating, and public pressure is mounting.

Why not develop a solution alongside the regulatory body to use rapid microbiological methods in such situations?

An example could be an emergency authorisation to use BactoSense data in scenarios where the water supply is at stake, or the adverse effects of disruption are disproportionately high compared to the risk. In the event of an incident, the cost savings of such a solution provide an immediate return on investment in BactoSense.

2. Make pipe flushing more economical

Today, the effectiveness of pipe flushing is often verified by cultivating bacteria using the heterotrophic plate count method.

However, when applied to flushing water analysis, this method has been reported to yield variable results, requiring operators to flush pipes for extended periods, often for several weeks. Flushing large pipes for such long durations can consume several tens of thousands of cubic metres of clean drinking water.

Therefore, moving towards adaptive flushing based on BactoSense monitoring data can reduce costs in the order of thousands to ten thousands of Euros per event.

Moreover, shortening the pipe flushing has also further social, economic and resource-saving benefits for situations in which:

The general water availability is limited (lack of capacity and public perception);

Contractors have to wait for clearance by microbiological lab tests;

It is generally challenging to divert flushing water.

3. Prevent microbial issues in temporarily stagnant water

Commissioning a new or maintained pipe segment as quickly as possible reduces the risk of microbial growth in adjacent parts of the distribution system, where flow stagnates due to temporary interruptions.

Where such contamination is detected, extensive pipe flushing procedures must be applied, wasting drinking water and further increasing the cost of the operation.

Book a demo today to explore how the use of BactoSense speeds up pipe operations, mitigates this risk and saves budget.

Comments